doi: 10.56294/sctconf2024857

Category: STEM (Science, Technology, Engineering and Mathematics)

ORIGINAL

Sustainable use of recycled glass powder-based geopolymer of organic soil stabilization

Uso sostenible de geopolímero a base de polvo de vidrio reciclado para la estabilización de suelos orgánicos

Khalaf Y. Khalaf1 *, Khalid R . Mahmood1 *

1Department of Civil Engineering, University of Anbar, Ramadi, Iraq.

Cite as: Khalaf KY, Mahmood KR. Sustainable use of recycled glass powder-based geopolymer of organic soil stabilization. Salud, Ciencia y Tecnología - Serie de Conferencias. 2024; 3:857. https://doi.org/10.56294/sctconf2024857

Submitted: 05-02-2024 Revised: 20-04-2024 Accepted: 07-06-2024 Published: 08-06-2024

Editor: Dr.

William Castillo-González ![]()

Note: Paper presented at the 3rd Annual International Conference on Information & Sciences (AICIS’23).

ABSTRACT

The foundation of any structure and construction of roads are most affected by different problems when it is constructed on weak soil such as organic soil for example. The use of recycled glass powder as a precursor in geopolymers improves soil properties (enhancing bearing capacity and reducing compressibility), as well as prevents glass waste from accumulating in landfills. The recycled glass powder (RGP) was added to the soil with different percentages(5,10,15,20 and 25)%. Sodium hydroxide (NaOH) is used as an alkaline solution. The chemical composition of RGP and the organic soil are determined by the X-ray fluorescence (XRF) test. Unconfined compressive strength (UCS) was conducted to investigate the mechanical behavior of specimens. The results show that increase in UCS in 7 and 14 days for the specimens treated with geopolymer compared to the natural soil specimens. The highest UCS value was 7,86 MPa at a curing time of 14 days and a curing temperature of 65C⁰ with 20 % RGP.

Keywords: Recycled Glass Powder; Geopolymer; Organic Soil Stabilization; Environmental.

RESUMEN

La cimentación de cualquier estructura y la construcción de carreteras se ven más afectadas por diferentes problemas cuando se construye sobre suelos débiles como, por ejemplo, suelos orgánicos. El uso de polvo de vidrio reciclado como precursor en geopolímeros mejora las propiedades del suelo (aumentando la capacidad portante y reduciendo la compresibilidad), además de evitar que los residuos de vidrio se acumulen en los vertederos. El polvo de vidrio reciclado (RGP) se añadió al suelo con diferentes porcentajes(5,10,15,20 y 25)%. Como solución alcalina se utilizó hidróxido de sodio (NaOH). La composición química del RGP y del suelo orgánico se determinó mediante la prueba de fluorescencia de rayos X (XRF). La resistencia a la compresión no confinada (UCS) se llevó a cabo para investigar el comportamiento mecánico de los especímenes. Los resultados muestran un aumento de la UCS en 7 y 14 días para las muestras tratadas con geopolímero en comparación con las muestras de suelo natural. El valor más alto de UCS fue de 7,86 MPa a un tiempo de curado de 14 días y una temperatura de curado de 65C⁰ con un 20 % de RGP.

Palabras clave: Polvo de Vidrio Reciclado; Geopolímero; Estabilización de Suelos Orgánicos; Medio Ambiente.

INTRODUCTION

Today Portland cement is the most common material for soil stabilization but the manufacturing of cement causes environmental effects due to the high emission of Carbone dioxide (CO2). Therefore, is very important to find alternative solutions for using cement in soil stabilization. This research investigates the feasibility of using a recycled glass powder-based geopolymer as an alternative solution for improving organic soil properties such as strength, and resistance to deformation. Also, this technique of soil stabilization will reduce the cost and be considered eco-friendly. Organic materials in soil come from animal and plant residues and contain carbon in composition. If the content of organic materials increases above 20 % the soil can be classified as organic soil according to ASTM D (2974).(1)

There are some previous studies investigating the engineering properties of the organic soil which are represented by high compressibility, low permeability, and low shear strength. Adel et al.(2) showed that the addition of lime to the soil affected shear strength parameters. Mohd et al.(3) studied the Stabilization of organic soil by adding lime- and added salt. Tastan et al.(4) studied the improvement of organic soil by adding fly ash. Moayedi et al.(5) studied the use of sodium silicate for stabilizing organic soil. Habbi(6) investigated the shear strength and compressibility of organic soil. Ali. F(7) showed that the improvement of organic soil can be done by mixing it with a chemical liquid consisting of lime, cement, and fly ash. Abbas et al.(8) showed that the increasing of organic content leads to an increase in optimum moisture content and reduces the maximum dry density. Boobathiraja et al.(9) studied the effect of using lime and cement to improve the UCS of organic. Refuel et al.(10) studied the behavior of organic soils by mixing them with lime and cement. Talib and Noriyuki(11) investigated the Stabilization of organic soils using bagasse ash. Adel et al.(12) investigated the improvement of the compressibility characteristics model of organic by adding lime in different percentages. Andersland and Al-Khafaji(13) found an approximating value of settlement of organic soil. Adejumo(14) showed that the consolidation settlement of organic soils was affected by an increase in the organic content. Thiyyakkandi and Annex(15) showed that the consolidation coefficient decreased with the increase in organic content. Wardwell and Nelson(16) showed the increase of organic content with increasing the coefficient of secondary compression (Cα) led to an increase void ratio of soil. Mustapa et al.(17) investigated the effect of gypsum content on the unconfined compressive strength of organic soil. Therefore, the organic soil must be treated before any construction. From above literature review shows that no application on soil stabilization by using geopolymer. Therefore, the use of recycled glass powder-based- geopolymer will be discussed in this study.

Materials

Organic soil

It was collected from the agricultural area in Anbar Governorate, west of Iraq. The soil samples were collected from depth (0,3 – 1) m. The soil was classified as Low plasticity organic silty clay (OL) according to the Unified Soil Classification System (USCS). Table 1 and table 2 show the physical properties of soil.

|

Table 1. Physical properties of soil |

||

|

Property |

Soil |

Standard |

|

Liquid Limit (LL) |

44 |

ASTM D4318 |

|

Plastic Limit (PL) |

27 |

ASTM D4318 |

|

Plastic index (PI) |

17 |

ASTM D4318 |

|

Specific gravity (Gs) |

2,45 |

ASTM D854 |

|

Organic content (OC)% |

20,8 |

ASTM D2974 |

|

% Passing sieve No. 200 |

86 |

ASTM D422 |

|

Unified Soil Classification System (USCS) |

OL |

ASTM D2487 |

|

Optimum Moisture Content (OMC)% |

20 |

ASTM D698 |

|

Maximum Dry Density (MMD) (KN/m3) |

15 |

ASTM D698 |

Recycled Glass Powder (RGP)

The waste glass powder was collected from a waste landfill in Ramadi city by crushing it using the traditional (metal mortar and pestle) method. Then it was sieved through sieve #200 and the particles finer than 75𝜇m used as the base of the geopolymer. The glass powder has a specific gravity (2,57) according to ASTM D854. Because of its high specific gravity compared to soil specific gravity (2,45), the MDD increase and OMC decrease when mixing with soil. Applying the XRF test on RGP shows that its content (SIO2, Al2O3, CaO, Fe2O3, MgO, ---etc.) and it is generally composed of a high percentage of silica (SIO2) (72,1 %). The (XRF is carried out at the Ministry of Industry and Minerals of Iraq. Table 2. shows the composition of recycled glass powder.

|

Table 2. Chemical composition of soil and recycled glass powder |

|||||||||

|

Chemical Composition (%) |

SIO2 |

Al2O3 |

CaO |

Fe2O3 |

MgO |

Na2O |

K2O |

SO3 |

Mn |

|

Organic soil |

39 |

20,91 |

20,4 |

5,74 |

9,28 |

1,24 |

1,31 |

1,10 |

0,08 |

|

RGP |

72,1 |

1,30 |

6,06 |

0,30 |

4,60 |

15,20 |

0 |

0,30 |

0 |

Sodium Hydroxide (NaOH) and Alkaline Solution

In this study, Sodium Hydroxide was used as an alkaline activator with a concentration of (4Molarity), and its properties are listed as shown in table 3.

|

Table 3. Properties of sodium hydroxide (NaOH) |

||||

|

Chemical formula |

Mass(g/mol) |

Purity (%) |

Density(g/cm3) |

PH |

|

NaOH |

40 |

98,5 |

2,13 @20C⁰ |

14 |

Testing Program

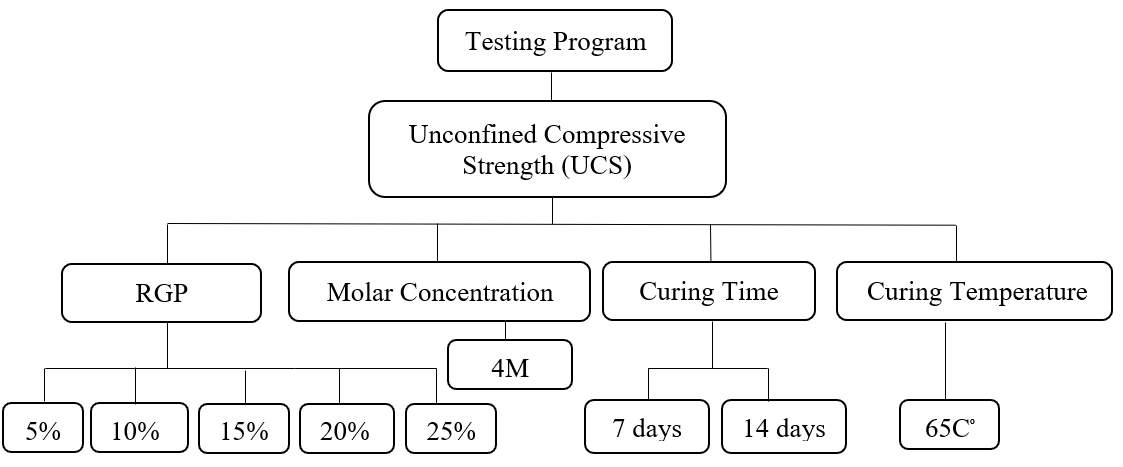

Testing Program is briefly explained as shown in figure 1.

Figure 1. Testing Diagram Chart

Unconfined Compressive Strength (UCS) Test

According to ASTM D2166, the unconfined compressive strength test was conducted on the specimens of (soil+ RGP) with different variations of RGP (5,10,15,20 and 25) %, constant molarity(4M), variation curing time (7,14) days and curing temperature 65C⁰. Fig.2 shows the processes examined by the UCS test.

Figure 2. Unconfined Compressive Strength test

RESULTS AND DISCUSSION

The results obtained from the unconfined compressive strength test are listed in table 4.

|

Table 4. Unconfined compressive strength values at(7and14) days |

||

|

Mixture |

7 days |

14 days |

|

UCS(MPa) |

UCS(MPa) |

|

|

Untreated soil (Compacted) |

0,2 |

0,2 |

|

Soil with 5 % RGP + NaOH |

3,57 |

4,36 |

|

Soil with 10 % RGP + NaOH |

4,5 |

5,23 |

|

Soil with 15 % RGP + NaOH |

5,57 |

5,68 |

|

Soil with 20 % RGP + NaOH |

6,34 |

7,86 |

|

Soil with 25 % RGP + NaOH |

6,25 |

7,58 |

The effect of two parameters was discussed in this research as follows.

The effect of recycled glass powder (RGP)

There is a relationship between the UCS values and the added percentage of recycled glass powder. Figure 3 shows that the values of UCS increase with increasing the percentage of recycled glass powder-based geopolymer up to 20 % for each curing period. The reason for the decrease in UCS up to 20 % RGP is because the ratio of (Al2O3) which is found in soil compared to (SiO2) will decrease and lead to make weak geopolymer.

Figure 3. UCS versus recycled glass powder content(%)

The effect of curing time

Also, there is a relationship between the unconfined compressive strength UCS values and the curing time. Fig.4 shows that the unconfined compressive strength increases for all treated specimens with increasing curing time (7 and 14) days in comparison to untreated soil specimens.

Figure 4. UCS values at (7 and 14) days curing period

CONCLUSIONS

According to the analysis of the results, some conclusions are obtained.

1. The values of (UCS) for all treated soil specimens increased gradually for all recycled glass powder content mixture (5,10,15,20) % because increasing in (SIO2) by adding RGP led to making a stronger binder.

2. The value of (UCS) will decrease with increasing the recycled glass powder above 20 % because the ratio of (Al2O3) compared to (SiO2) will decrease which leads to making a weak geopolymer.

3. The values of (UCS) increase with increasing curing time at (65C⁰).

4. There is a positive effect of using recycled glass powder-based geopolymer for stabilizing organic soil, and recycled glass powder is an eco-friendly soil stabilization that contains high silica (72,1 %).

REFERENCES

1. ASTM D2974, “Standard Test Methods for Determining the Water (Moisture) Content, Ash Content, and Organic Material of Peat and Other Organic Soils,” ASTM Int., pp. 1–4, 2020.

2. A. H. Majeed, M. S. Al-Soud, and Z. H. Sadiq, “Improvement of Shear Strength Parameters of Model Organic Soils,” J. Eng. Sustain. Dev., vol. 20, no. 05, pp. 213–224, 2016.

3. N. Z. Mohd et al., “Stabilisation of organic clay using lime-added salt,” no. January 2007, 2014.

4. E. O. Tastan, T. B. Edil, C. H. Benson, and A. H. Aydilek, “Stabilization of Organic Soils with Fly Ash,” J. Geotech. Geoenvironmental Eng., vol. 137, no. 9, pp. 819–833, Sep. 2011, doi: 10.1061/(ASCE)GT.1943-5606.0000502.

5. H. Moayedi, B. B. K. Huat, F. Moayedi, A. Asadi, and A. Parsaie, “Effect of sodium silicate on unconfined compressive strength of soft clay,” Electron. J. Geotech. Eng., vol. 16 C, pp. 289–295, 2011.

6. Z. M. Habbi, “Compressibility and shear strength characteristics of model organic soils,” Master Thesis of Science in Civil Engineering, Al-Mustansiriyah University, 2005.

7. F. Ali, “Stabilization of residual soils using liquid chemical,” Electron. J. Geotech. Eng., vol. 17 B, pp. 115–126, 2012.

8. A. Abbas, A. H. Majeed, and I. M. Hassan, “Compaction and Strength of Slightly Organic Soil,” J. Build. Res. Cent., vol. 4, no. 1, pp. 1–19, 1985.

9. S. Boobathiraja, P. Balamurugan, M. Dhansheer, and A. Adhikari, “Study on strength of peat soil stabilized with cement and other pozzolanic materials,” Int. J. Civ. Eng. Res., vol. 5, no. 4, pp. 431–438, 2014.

10. T. Rabbee and I. M. Rafizul, “Strength and compressibility characteristics of reconstituted organic soil at Khulna region of Bangladesh,” Int. J. Eng. Technol., vol. 2, no. 10, pp. 1672–1681, 2012.

11. M. K. A. Talib and Y. Noriyuki, “Highly organic soil stabilization by using sugarcane Bagasse Ash (SCBA),” in MATEC Web of Conferences, EDP Sciences, 2017, p. 7013.

12. A. H. Majeed, M. S. Al-Soud, and Z. H. Sadiq, “Improvement of compressibility characteristics of model organic soils,” J. Eng. Sustain. Dev., vol. 21, no. 2, pp. 80–92, 2017.

13. O. B. Andersland and A.-A. W. N. Al-Khafaji, “Organic material and soil compressibility,” J. Geotech. Eng. Div., vol. 106, no. 7, pp. 749–758, 1980.

14. T. E. Adejumo, “Effect of organic content on compaction and consolidation characteristics of logos organic clay,” Electron. J. Geotech. Eng., vol. 17, 2012.

15. S. Thiyyakkandi and S. Annex, “Effect of organic content on geotechnical properties of Kuttanad clay,” Electron. J. Geotech. Eng., vol. 16, pp. 1653–1663, 2011.

16. R. E. Wardwell and J. D. Nelson, “Settlement of sludge landfills with fiber decomposition,” PROCEEDINGS OF THE INTERNATIONAL CONFERENCE ON SOIL MECHANICS AND FOUNDATION …, 1981.

17. N. A. Mustapa et al., “Gypsum Stabilization of Organic Soil: Strength And Compressibility,” Suranaree J. Sci. Technol., vol. 28, no. 4, 2021.

FINANCING

None.

CONFLICT OF INTEREST

None.

AUTHORSHIP CONTRIBUTION

Conceptualization: Khalaf Y. Khalaf, Khalid R. Mahmood.

Research: Khalaf Y. Khalaf, Khalid R. Mahmood.

Writing - original draft: Khalaf Y. Khalaf, Khalid R. Mahmood.

Writing - revision and editing: Khalaf Y. Khalaf, Khalid R. Mahmood.